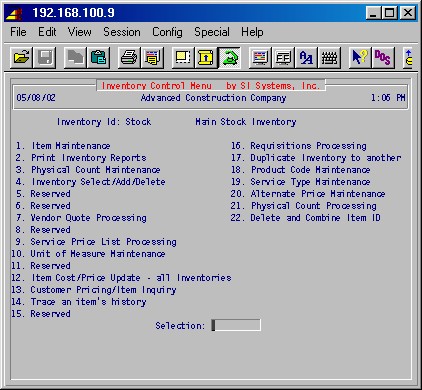

From the main menu, if #8 Inventory-Stock/Requisitions is selected, this inventory control menu is displayed.

8-1 Item Maintenance - This selection allows you to input information concerning each inventory item, and update or change that information as required. You have the option of expanded entry allowing very detailed input of various selling prices and labor rates, or abbreviated entry for faster input of the basic description fields.

8-2 Print Inventory Reports - These procedures will print various inventory reports as of a specified date and specified ranges of report parameters. These reports will list the item IDs, description, qualifier, DCI number, number on hand, cost/UOM, the extended amount, and total.

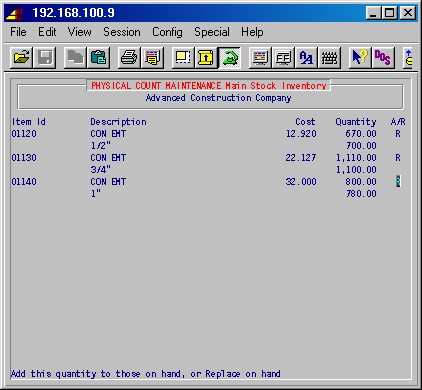

8-3 Physical Count Maintenance - This procedure allows

you to record an inventory quantity and cost, specifying whether to add this

quantity to those on hand or replace those on hand. This procedure is normally

used only for manual updating of the inventory after the annual inventory

count. Routine inventory receiving is done in the purchase order system or using

steps 8-14: Trace an Item's History. If you are not using

the purchase order module, inventory receiving may also be done here.

8-4 Inventory Select/Add/Delete - The system has the capability to allow you to maintain several inventories if desired. For instance, some companies will maintain a main stock inventory, job site inventory for selected jobs, and truck inventories. This procedure will list all inventories you have set up in order to let you switch between them for the purpose of item maintenance and inventory reports. It also allows you to add a new inventory. The current inventory is displayed at the top of the input area on procedures that allow for different inventories.

This procedure also allows (with proper permission) you to delete an inventory,

which would be done when you are completely through using a job/truck inventory

and you want to put it out of commission. This will delete any reference to

this job/truck inventory out of the inventory

system.

8-7 Vendor Quote Processing - These procedures will allow you record quotes from one or more vendors for each inventory item, print quote lists and spread sheets, and do maintenance on usage history.

8-9 Service Price List Processing - The procedures in this area allow you to identify, price, and produce a list of inventory items that you want the service technicians to carry with them in their service trucks. This list will assist the technicians in pricing the parts used on a service order to enable them to deliver an invoice at the time the service is performed.

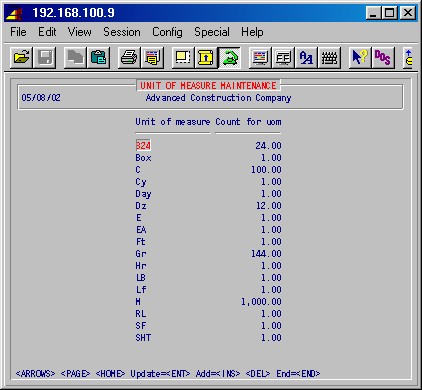

8-10 Unit of Measure Maintenance - This selection allows you to specify various units of measure and the count that they represent. The system comes with the most common units of measure as shown in the screen below.

8-12 Item Cost Update- All Inventories - Item cost normally is not changed manually because this is updated when you enter the cost in inventory receiving maintenance. However, this procedure will allow you to input new cost data for specified item IDs for all inventories.

8-13 Item inquiry - This procedure allows you to display inventory information for a specified item ID. The system will display current inventory locations, quantity on hand, list selling price, and cost price.

8-14 Trace an Item's History - This procedure provides an alternative method of receiving new inventory purchases into the inventory system if you are not using the purchase order system. If you are using the PO system, receiving should be done in that area.

8-16 Requisitions Processing - These procedures allow you to create and print requisitions, as well a perform various requisition maintenance activities. You may requisition material from the main stock inventory to a job, a job site inventory, a truck inventory or a service order, or requisition from the job or truck inventory back to the main stock inventory, or from one truck inventory to another.

8-17 Duplicate Inventory to another - This procedure allows you to make a copy of an inventory or to merge one inventory into another.

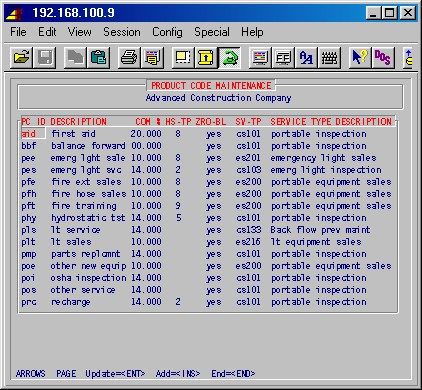

8-18 Product Code Maintenance - This procedure allows you to set up and maintain product codes. Product codes allow you to identify items in inventory as belonging to groups.

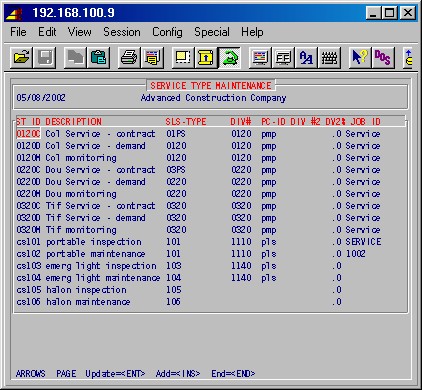

8-19 Service Type Maintenance - This procedure allows you to set up and maintain service types. Service types parallel AR sales types (as set up in 1-4-1: Sales Type Maintenance) and controls your accounting in service, but this feature allows you to have multiple service types without having to set up an AR sales type for each.

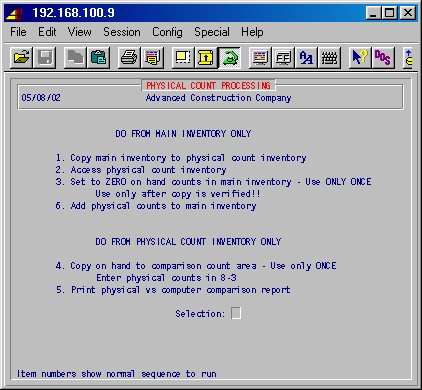

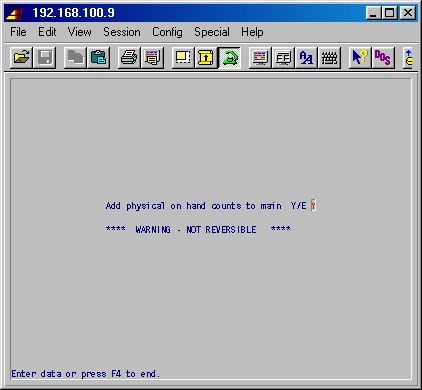

8-20 Alternate Price Maintenance - This procedure allows you to set up and maintain alternate prices (price schedules) for items, allowing different customers to have different prices for each item. 8-21 Physical Count Processing - This procedure allows you to create a separate database only containing only inventory data, used when doing a physical counts of the inventory. The on-hand quantities in the main database inventory can then be set to zero, allowing normal requisitions, sales and receiving to continue while physical counts are entered in the inventory database. Once complete, the physical counts in the inventory database can be added back into the main database.

Sales types (departments) and GL account numbers

Sales types (departments) should already have been set up as part of the AR

module setup in 1-4-1.

Select 7-1-1: Job Description Maintenance and ensure the job STOCK is set up right (e.g. sales type ID, tax IDs).

Select 8-1: Inventory Maintenance and ensure that the item with ID :M has been set up.

Select 8-10: Unit of Measure Maintenance and set up the unit of measures you'll be using.

Select 8-18: Product Code Maintenance and set up product codes, if desired.

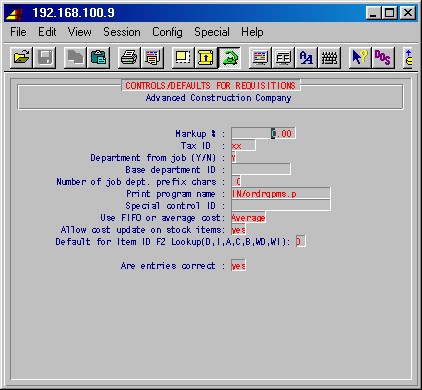

Used in 8-16: Requisitions Processing.

Markup %

Enter the percentage that item cost is to be marked up when requisitioning to

a job.

Tax ID

Enter the tax ID for tax on item requisitioned to a job.

Department from job (Y/N)

If you want the department (sales type) for the requisition to come from the

job, enter Yes. If you want the department to be the default below, enter

No.

Base department ID

Enter the default department (sales type) for requisitions to jobs.

Number of job dept. prefix chars

Normally 0.

Print program name

Normally IN/ordrqpms.p

Special control ID

Leave blank.

Use FIFO or average cost

Specify for stock requisitions, POs and Service Orders whether the system uses

the actual cost of an item (FIFO) or a weighted average as a basis for

cost. Answer <A>verage or <F>ifo. If you haven't been

using FIFO, you can't just switch, so answer <A>.

Allow cost update on stock items

If answered no the system prevents you from changing the cost on stock items

during requisition.

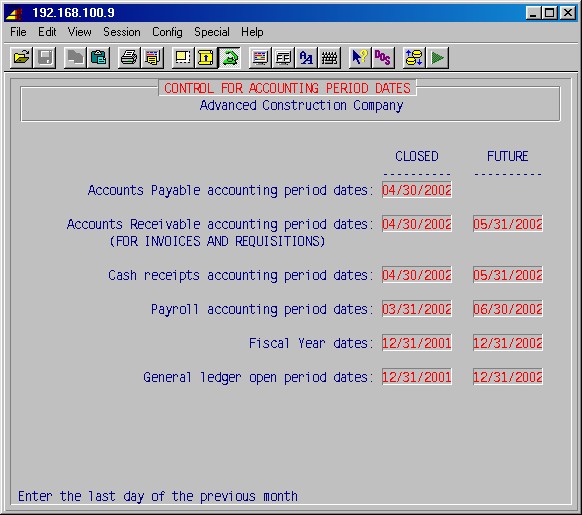

Enter appropriate dates to control the accounting dates (new transaction dates entered will have to be later than the "closed" dates and before or on the "future" dates). The purpose of these "date locks" is to prevent inadvertent entry of wrong dates, e.g. wrong year.

Accounts Receivable closed accounting period date

Operators will not be allowed to enter requisition dates with or earlier than this date.

Accounts Receivable future date limit

Operators will not be allowed to enter requisition dates later than this date.Top

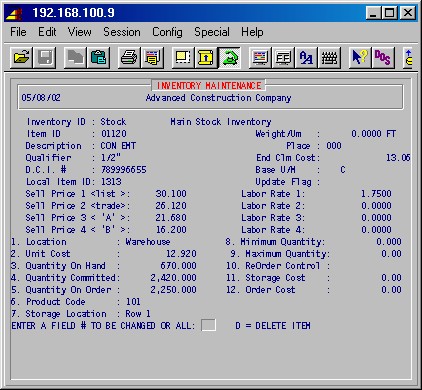

This selection allows you to input information concerning each inventory item, and update or change that information as required. This selection will prompt:

Abbreviated entry : NO

You may choose from two input screens here. The abbreviated entry screen allows

you to input or make changes to the principal components of the inventory item

description. The expanded entry screen allows you additional detail and options.

We will explain both input screens in

detail.

Selecting the default NO by pressing just ENTER, will display a detailed input screen which will be displayed in three sets of fields, one set at a time, starting at the top 1/3 of the screen. You have the ability to edit each set when it is displayed.

This data input screen with all three sets of fields is represented as

follows (items in bold are examples):

TopItem ID:

If you are entering an existing item ID

Type the item ID [H] and press ENTER. The first set of ten fields will be displayed on the upper 1/3 of the screen and will be filled in with any data previously entered into the system.If you are entering a new item ID

Type up to a 15 character (numbers and letters) ID to identify this item. If this item ID has not been entered previously, the system will prompt:No item exists. Do you want to create a new one ? YES

Press just ENTER to continue defining a new item, or type NO ENTER to position the cursor back on the item ID. You may now retype an ID, or press just ENTER to exit this procedure and return to the Inventory Control Menu.

Description:

This is the primary description. Type a description (up to 25 characters) which will categorize this item by type. The primary description should be broad - from the general to the specific - with a space between each characteristic. The qualifier to complete the description will be specified below. As in the sample screen above, the description CON EMT describes "conduit, emt".Qualifier:

This will qualify the main description by size, color, number, etc. Type a qualifier (up to 25 characters) to complete the description (Example: 3/4" describes 3/4" EMT).D.C.I. #:

This is the industry standard number assigned to this item. Type this number (up to 20 characters) or leave the question mark (?) if you don't know the DCI #.Local item ID:

This is a place for an alternate item ID for this item if needed. Otherwise, leave the question mark (?).Weight/Um:

This is the weight of this item per the unit of measure for industry standard packaging quantities. Type the weight and press ENTER; then type the unit of measure (from the unit of measure file in 8-10: Unit of measure maintenance) and press ENTER. (When 8-9: Service Price List Processing is used, the Weight field is used to store the service list price.)Place:

This allows you to specify the place (position) in the list of main descriptions where you want this item to appear. If you leave this field at 000, the system will sort and display the inventory items in alpha-numeric order by main description then qualifier.End clm cost:

Type the end column cost for this item here.Base U/M:

Type the unit of measure used for pricing this item as found in the unit of measure file in 8-10: Unit of measure maintenance.Update flag:

This indicates whether the prices for this item will be automatically updated from industry pricing services.Custom

This selection gives access to a separate user defined screen as set up in 13-8-16: User Defined Data Maintenance, with as many as 17 fields to hold additional information about an item.

When this set of ten fields is completed, any field may be changed by typing the number of the field and pressing ENTER. The field will be highlighted to indicate it is in an edit mode. Type the new data and press ENTER.When you are finished making entries to the first set of fields, press ENTER and a second set of eight fields will be displayed below the first set.

Sell price 1 <list>:

Type your list selling price here. If one of the national price updating services is used, this will be filled in by the lowest selling price supplied.Sell price 2 <trade>:

Type your trade selling price here. If one of the national price updating services is used, this will be filled in by the next lowest selling price supplied.Sell price 3 <'A'>:

Type your sell price per trade service pricing 'A' guidelines here. If one of the national price updating services is used, this will be filled in by the third lowest selling price supplied.Sell price 4 <'B'>:

Type your sell price per trade service pricing 'B' guidelines here. If one of the national price updating services is used, this will be filled in by the fourth lowest selling price supplied.Labor rates are used in conjunction with the unit estimating module.

Labor rate 1:

Type the labor rate per hour for a slower than normal installation.Labor rate 2:

Type the labor rate per hour for a normal installation.Labor rate 3:

Type the labor rate per hour for a fast installation.Labor rate 4:

Type the book value per hour for labor.When this set of eight fields is completed, any field may be changed by typing the number of the field and pressing ENTER. The field will be highlighted to indicate it is in an edit mode. Type the new data and press ENTER. When you are finished making entries to this

second set of fields, press ENTER and a third set of twelve fields will be displayed below the first and second set.Location:

Type the location (up to twelve characters) of the inventory item. This is normally left warehouse for the main inventory, but may be more specific if inventory is stored in multiple locations.Unit cost:

Type the unit cost price of this item per the base unit of measure specified above.Quantity on hand:

This field allows you to manually adjust the quantity on hand, however this figure will be kept current by the system if you are using the purchase order and service order modules.Quantity committed:

This field allows you to manually adjust the quantity committed, however this figure will be kept current by the system if you are using the service order module.Quantity on order:

This field allows you to manually adjust the quantity on order, however this figure will be kept current by the system if you are using the purchase order module.Product code:

You may enter a sales or product code (up to 12 characters) for this item which is unique to your company if desired, from list of sales type IDs entered in 1-4-1.Storage location:

Type your warehouse location code (up to 25 characters) if desired.Minimum quantity:

This is a quantity which you determine is the minimum you want to have on hand. This will cause this item to print on the reorder report when the quantity falls below this minimum number.Maximum quantity:

This is the maximum quantity you want to have on hand. This number will aid you in reordering.Reorder control:

This feature is not available at this time.Storage cost:

Type your cost of storage here if desired.Order cost:

Type your cost of ordering this item here if desired.When this set of twelve fields is completed, any field may be changed by typing the number of the field and pressing ENTER. The field will be highlighted to indicate it is in an edit mode. Type the new data and press ENTER. When you are finished making entries to this third set of fields, press ENTER twice and the cursor will return to the item ID field ready for another item entry.

To exit this procedure, press ENTER again and you will return to the Inventory Control Menu.

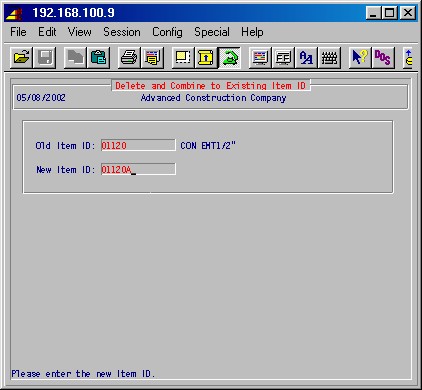

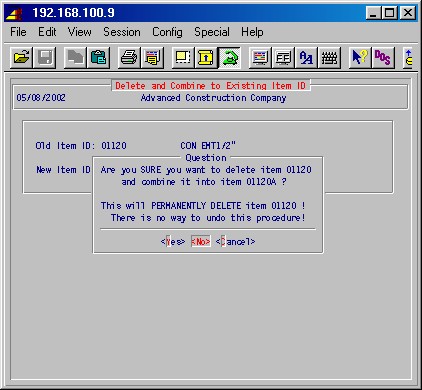

Deleting an inventory item

To delete an inventory item, type the item ID and press ENTER. The first set of fields will be displayed and the bottom line menu will prompt you to enter a field to be changed. Here you may delete the entire inventory item record by typing "d" and pressing ENTER. The system will prompt:Do you really want to delete this item from this inventory ?: NO

If you are sure, type YES ENTER and the item will be deleted from the system.

The abbreviated entry screen allows you to input or make changes to the principal components of the inventory item description on an abbreviated input screen. At the prompt:

Abbreviated entry : NO

Type YES ENTER to choose the abbreviated screen. This screen will look like this :

Item ID:

If you are entering an existing item ID

Type the item ID [H] and press ENTER. The screen will be filled in with any data previously entered into the system.If you are entering a new item ID

Type up to a 15 character (numbers and letters) ID to identify this item. If this item ID has not been entered previously, the system will prompt:No item exists. Do you want to create a new one ? YES

Press just ENTER to continue defining a new item, or type NO ENTER to position the cursor back on the item ID. You may now retype an ID, or press just ENTER to exit this procedure and return to the Inventory Control Menu.

Description:

This is the primary description. Type a description (up to 25 characters) which will categorize this item by type. The primary description should be broad - from the general to the specific - with a space between each characteristic. The qualifier to

complete the description will be specified below. As in the sample screen above, the description CON EMT describes "conduit, emt".Qualifier:

This will qualify the main description by size, color, number, etc. Type a qualifier (up to 25 characters) to complete the description (Example: 3/4" describes 3/4" EMT).

Base U/M:

Type the base unit of measure used for pricing this item as found in the unit of measure file in 8-10.

Local item ID:

This is a place for an alternate item ID for this item, if needed. Otherwise leave blank.

DCI/Bar Code ID:

This is the industry standard number assigned to this item. Type this number (up to 20 characters) or leave the question mark (?) if you don't know the DCI #.

Sales Type ID:

Enter the sales type [H] this item is normally posted to.

Division ID:

Enter the division [H] this item is normally posted to.

Tax Control Flag:

Normally leave blank.

List Price 1 <'L1'>:

Type your list selling price here. If one of the national price updating services is used, this will be filled in by the lowest selling price supplied.

List Price 2 <'L2'>:

Type your trade selling price here. If one of the national price updating services is used, this will be filled in by the next lowest selling price supplied.

List Price 3 <'L3'>:

Type your sell price per trade service pricing 'A' guidelines here. If one of the national price updating services is used, this will be filled in by the third lowest selling price supplied.

List Price 4 <'L4'>:

Type your sell price per trade service pricing 'B' guidelines here. If one of the national price updating services is used, this will be filled in by the fourth lowest selling price supplied.

Average Cost:

Type the unit cost price of this item per the base unit of measure specified above.

Reorder control:

This feature is not available at this time.

Vendor ID:

Enter the ID of the vendor normally supplying this item, if applicable.

Quantity On Hand:

This field allows you to manually adjust the quantity on hand, however this figure will be kept current by the system if you are using the purchase order and service order modules.

Quantity On Order:

This field allows you to manually adjust the quantity on order, however this figure will be kept current by the system if you are using the purchase order module.

Quantity Committ:

This field allows you to manually adjust the quantity committed, however this figure will be kept current by the system if you are using the service order module.Minimum Quantity:

This is a quantity which you determine is the minimum you want to have on hand. This will cause this item to print on the reorder report when the quantity falls below this minimum number.Maximum Quantity:

This is the maximum quantity you want to have on hand. This number will aid you in reordering.Product code:

You may enter a sales or product code (up to 12 characters) for this item which is unique to your company if desired. This groups items for the same markup and/or the same commission percentage.Commission %

Not generally used.Assembly Flag

Enter YES if this item is an assembly of other items.Custom Data

This selection gives access to a separate user defined screen as set up in 13-8-16:User Defined Data Maintenance, with as many as 17 fields to hold additional information about the item.When this set of fields is completed, any field may be changed by typing the number of the field and pressing ENTER. The field will be highlighted to indicate it is in an edit mode. Type the new data and press ENTER.

If you wish to see or print a list of purchases for this item press P and ENTER.

If this item is an assembly and you want to enter or see what items make up this assembly, press A and ENTER. This will take you to the following screen :

SQ

This is a line (sequence) number automatically assigned by the system.ITEM ID

Enter the ID [H] of an item that is part of this assembly.ITEM DESCRIPTION

The description of the selected item will be displayed.QUANTITY

Enter the quantity of this item used in this assembly.You may use the ARROW, PAGE and ENTER keys to highlight and update a line. Use the DEL key to delete a line and the INS key to add a line.

Press END when done, and you'll be returned to the previous screen.

When you are finished making entries to this third set of fields, press ENTER and the cursor will return to the Item ID field ready for another item entry.

To exit this procedure, press ENTER again and you will return to the Inventory Control Menu.

Deleting an inventory item

To delete an inventory item, type the item ID and press ENTER. The first set of fields will be displayed and the bottom line menu will prompt you to enter a field to be changed. Here you may delete the entire inventory item record by typing "d" and pressing ENTER. The system will prompt:Do you really want to delete this item from this inventory ?: NO

If you are sure, type YES ENTER and the item will be deleted from the system.

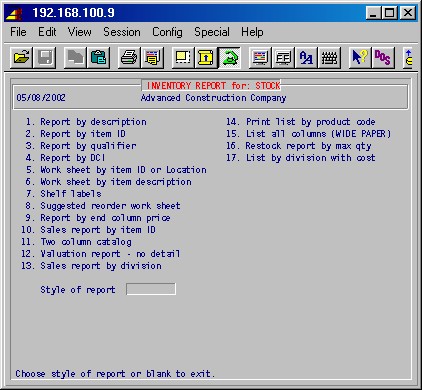

These procedures will print various inventory reports for the inventory selected (in 8-4), as of the date run and specified range of report parameters.

Most of these reports will list the item IDs, description, qualifier, DCI number, number on hand, cost/UOM, the extended amount, and total.

Style of report

Type the number of the report you want and press ENTER.

You'll then be prompted:

Print items with update flags only? NO

Answer Yes if you want to print only those items you have flagged for automatic updates from industry pricing services. Press just ENTER to print all items.

Print items with zero quantity? yes

Answer No if you do not want items with zero quantities printed.

Are entries correct: yes

Check you entries and type NO ENTER to go back and make changes, or press just ENTER to continue. You'll then be prompted for the printer and number of copies.TopNOTE: When you perform these procedures, the system will notify you that these reports are being printed; however, it may be several minutes before your printer starts printing the report. This is because the system may take some time to process the large number of items on the printout.

This selection will print a report of selected inventory items in description order. The system will prompt:

Beginning description:

Ending description:

Beginning item ID:

Ending item ID:

Specify a range of descriptions and/or item IDs by typing the beginning and ending descriptions (and/or IDs), or a particular description (and/or ID) by putting it in both fields, or all inventory items by leaving all fields blank.

Which Price Column:

Specify which price column to print (L1, L2, L3 or L4).

This selection will print a report of selected inventory items by item IDs, in alpha-numeric order. The system will prompt:

Beginning item ID:

Ending item ID:

Specify a range of descriptions and/or item IDs by typing the beginning and ending descriptions (and/or IDs), or a particular description (and/or ID) by putting it in both fields, or all inventory items by leaving all fields blank.

Which Price Column:

Specify which price column to print (L1, L2, L3 or L4).

Use Regular or Local Item ID?:

If you type L the report will be printed in order of Local Item IDs rather than regular item ID, and the above item ID range will apply to local item IDs.

This selection will print a report of selected inventory items in qualifier

order. The system

will prompt:

Beginning description:

Ending description:

Beginning item ID:

Ending item ID:

Specify a range of descriptions and/or item IDs by typing the beginning and ending descriptions (and/or IDs), or a particular description (and/or ID) by putting it in both fields, or all inventory items by leaving all fields blank.

Which Price Column:

Specify which price column to print (L1, L2, L3 or L4).

This selection will print a report of selected inventory items in DCI # (the industry standard number assigned to this item), order. The system will prompt:

Beginning DCI:

Ending DCI:

Specify a range of DCI numbers by typing the beginning and ending DCI numbers, or a particular DCI number by putting it in both fields, or all inventory items by leaving both fields blank.

TopWhich Price Column:

Specify which price column to print (L1, L2, L3 or L4). 8-2-5: Inventory Work Sheet by Item ID This selection will print an inventory work sheet in item ID order showing the complete description with the qualifier for each item. A work sheet is simply a listing, used to take physical inventory counts of the inventory items, with the base unit of measure adjacent to a blank line to mark the actual quantity on hand.

The system will prompt:

Print by storage location:________

Beginning item ID:

Ending item ID:

Specify a range of item IDs by typing the beginning and ending IDs, or a particular item ID by putting it in both fields, or all inventory items by leaving both fields blank.Beginning Prod Code:

Ending Prod Code:

Specify a range of product codes by typing the beginning and ending product codes, or a particular product code by putting it in both fields, or all inventory items by leaving both fields blank.

Beginning Location: Ending Location:

This selection will print an inventory work sheet in item ID order showing

the complete description with the qualifier for each item. A work sheet

is simply a listing, used to take physical inventory counts of the inventory

items, with the base unit of measure adjacent to

a blank line to mark the actual quantity on hand.

The system will prompt:

Print by storage location:________

Beginning item ID:

Ending item ID:

Specify a range of item IDs by typing the beginning and ending IDs, or a particular item ID by putting it in both fields, or all inventory items by leaving both fields blank.

Beginning Prod Code:

Ending Prod Code:

Specify a range of product codes by typing the beginning and ending product codes, or a particular product code by putting it in both fields, or all inventory items by leaving both fields blank.Beginning Location: Ending Location:

This selection will print an inventory work sheet in item description order showing the complete description with the qualifier for each item. A work sheet is simply a listing, used to take the physical inventory count of the inventory items, with the base unit of measure adjacent to a blank line to mark the actual quantity on hand.

The system will prompt:

Beginning description:

Ending description:

Specify a range of qualifier descriptions by typing the beginning and ending description, or a particular item description by putting it in both fields, or all inventory items by leaving both fields blank.

Beginning item ID:

Ending item ID:

Specify a range of item IDs by typing the beginning and ending IDs, or a particular item ID by putting it in both fields, or all inventory items by leaving both fields blank.

Beginning Prod Code:

Ending Prod Code:

Specify a range of product codes by typing the beginning and ending product codes, or a particular product code by putting it in both fields, or all inventory items by leaving both fields blank.

This selection will print inventory shelf labels, eleven to a page, with your SKU # (item ID), inventory description, and qualifier, DCI #, minimum and maximum quantities, unit of measure, and weight.

The system will prompt:

Beginning item ID:

Ending item ID:

Specify a range of item IDs by typing the beginning and ending IDs, or a particular item ID by putting it in both fields, or all inventory items by leaving both fields blank.

This selection will print a reorder worksheet showing suggested reorder amounts calculated by the system. The list will be in numerical order by item IDs, with a complete description, on hand, minimum quantity, maximum quantity, and reorder quantity, cost, and extended amount.

The system will prompt:

Beginning item ID:

Ending item ID:

Specify a range of item IDs by typing the beginning and ending IDs, or a particular item ID by putting it in both fields, or all inventory items by leaving both fields blank.

Beginning Prod Code:

Ending Prod Code:

Specify a range of product codes by typing the beginning and ending product codes, or a particular product code by putting it in both fields, or all inventory items by leaving both fields blank.

Min/Max list only:

Answer Yes to print a report that only lists item ID, minimum quantity, maximum quantity, description and unit of measure for each selected item. If you answer No the report will print all items where the minimum quantity is greater than zero and the on-hand quantity is less than the minimum quantity, listing item ID, on-hand, minimum quantity, maximum quantity, suggested order quantity, description, DCI code, cost, unit of measure and extended amount for each selected item.

This selection will print a report by end column price.

This selection will prompt:

Beginning code:

Ending code:

Specify a range of item IDs by typing the beginning and ending end column code numbers, or a particular code number for one item by putting it in both fields, or all inventory items by leaving both fields blank. This is used only by those companies which have used the end column price column for special category codes instead of actual prices.

This selection will print a sales report in item ID order, showing the complete description, the selling prices, cost, month-to-date and year-to-date quantities sold, and the year-to-date extended amount based on the list price.

The system will prompt:

Usage date:

Enter any date in the month and year you want to report.

Beginning item ID:

Ending item ID:

Specify a range of item IDs by typing the beginning and ending IDs, or a particular item ID by putting it in both fields, or all inventory items by leaving both fields blank.

Beginning local item ID:

Ending local item ID:

Specify a range of local item IDs by typing the beginning and ending local item IDs, or a particular local item ID by putting it in both fields, or all inventory items by leaving both fields blank.

Beginning description:

Ending description:

Specify a range of qualifier descriptions by typing the beginning and ending description, or a particular item description by putting it in both fields, or all inventory items by leaving both fields blank.

Location:

Normally leave blank. If you enter a character here, the report will be limited to items that have this character as the third character from the left in "Storage Location".

Subtotal by group:

If you answer Yes here, you'll get a subtotal for each group of items where the first four characters of the item ID are identical.

This selection will print a two column catalog in item ID order, showing item ID, description, price and unit of measure.

The system will prompt:

Beginning item ID:

Ending item ID:

Specify a range of item IDs by typing the beginning and ending IDs, or a particular item ID by putting it in both fields, or all inventory items by leaving both fields blank.

Beginning local item ID:

Ending local item ID:

Specify a range of local item IDs by typing the beginning and ending local item IDs, or a particular local item ID by putting it in both fields, or all inventory items by leaving both fields blank.

Beginning description:

Ending description:

Specify a range of qualifier descriptions by typing the beginning and ending description, or a particular item description by putting it in both fields, or all inventory items by leaving both fields blank.

Beginning DCI:

Ending DCI:

Specify a range of DCI numbers by typing the beginning and ending DCI numbers, or a particular DCI number by putting it in both fields, or all inventory items by leaving both fields blank.

Which price column:

Specify which price column to print (C for cost, L1, L2, L3, L4 or leave blank to not print any price). You may also type end here, if you want to exit this report without printing it.

This selection will calculate and print the value of the selected inventory, showing total negative value and total positive value, based on quantity on hand and cost.

The system will prompt:

List prefixes of inventories to skip (Trucks, jobs, etc.):

Here you may enter up to 20 prefixes of inventories you wish to exclude from the report. Any inventory with an ID beginning with one of these prefixes will be excluded.

This selection will print a sales report of items in groups of divisions, showing the complete description, the selling prices, cost, month-to-date and year-to-date quantities sold, and the year-to-date extended amount based on the list price.

The system will prompt:

Usage date (last day of month):

Enter the date of the last day in the month and year you want to report.

This selection will print a list of selected items grouped by product code, showing product code, item ID, description, qualifier, tax code, the four list prices and, optionally, a cost column.

The system will prompt:

Enter Beginning Product Code:

Enter Ending Product Code:

Specify a range of product codes by typing the beginning and ending product codes, or a particular product code by putting it in both fields, or all inventory items by leaving both fields blank.

Print Cost:

Answer Yes if you also want the cost column printed.

Print By Desc OR Item ID:

Type D if you want the report to list in order of description within the product code groups, otherwise I to list by item ID.

OK To Print Report:

Answer Yes when you're ready to print the report.

This selection will print a list of selected items showing item ID, description, qualifier, DCI number, alternate item ID, product code, unit of measure, the four list prices and cost.

The system will prompt:

Beginning item ID:

Ending item ID:

Specify a range of item IDs by typing the beginning and ending IDs, or a particular item ID by putting it in both fields, or all inventory items by leaving both fields blank.

This selection will print a list of selected items where the max quantity is greater than zero, showing storage location, item ID, description, qualifier, and a line to write a count, with a new page for new each first character of the storage location.

The system will prompt:

Beginning item ID:

Ending item ID:

Specify a range of item IDs by typing the beginning and ending IDs, or a particular item ID by putting it in both fields, or all inventory items by leaving both fields blank.

Location (BLANK ALL):

If you enter a character here, the report will be limited to items that have this character as the first character in "Storage Location".

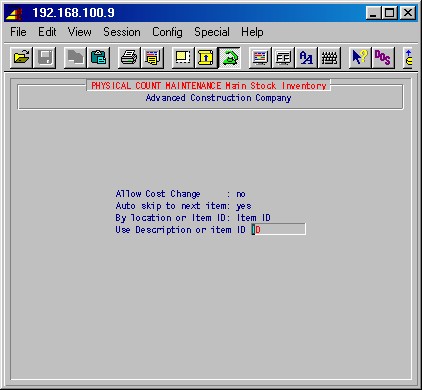

NOTE: This procedure does not update accounting.

This procedure allows you to record an inventory quantity and cost, specifying whether to add this quantity to those on hand or replace those on hand.

This procedure is normally used only for manual updating of the inventory after the annual inventory count. Routine inventory receiving is done in the purchase order system. If you are not using the purchase order module, inventory receiving should be done in 8-14: Trace an Item's History, not here.

Corrections are made by specifying the item ID you wish to change or correct, and making a reversing entry, by entering the same cost and a negative quantity, which will have the effect of canceling the original entry. Then specify the item ID a third time, and enter the correct quantity.

This selection will first prompt:

Allow cost change:

Answer Yes if you want to be able to change the costs of items.

Auto skip to next item:

Answer Yes if you want to have the system automatically suggest the next item when done with an item.

"use description or item ID: Item ID

If you answered Yes to Auto skip to next item, you'll be prompted:

Use Description or item ID

Type D if you want the system to automatically advance to the next item in description order; otherwise I.

Next the system will display the following input screen :

Item ID:

Type the item ID here and press ENTER. The description, previous cost, and quantity on hand will be displayed by the system.

Description:

The description will only be displayed here and may not be changed in this procedure.

Cost:

The previous cost will be displayed highlighted to indicate it is in the edit mode. Type the new cost figure here if it is different.

Quantity:

Type the quantity you wish to add or subtract from the quantity on hand. If you wish to subtract from the quantity on hand (as in the case of a reversing entry for a correction) just enter a negative number.

After the quantity has been entered, the system will prompt:

Add this quantity to those on hand, or Replace on hand

If you are adjusting the quantity on hand as you may need to do after the

annual inventory count, type Replace ENTER here. The cursor will

now be positioned for you to input another item ID. If you want to exit this

area, leave the Item ID blank and press ENTER again and you

will return to the #8 Inventory-stock/requisitions menu.

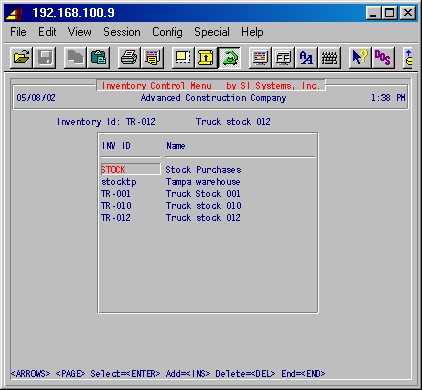

The system has the capability to allow you to maintain several inventories

if desired. For instance, some companies will maintain a main stock inventory,

job site inventory for selected jobs, and truck inventories. This procedure

will list all inventories you have set up in order to let

you switch between them for the purpose of item maintenance and inventory reports.

It also allows you to add a new inventory.

This selection will display the following input screen :

Use the ARROW or PAGE keys to highlight the inventory you want and press ENTER to select it.

Press END to leave this procedure without changing inventory.

Press INS if you wish to create a new job site inventory and the system will prompt:

ID of new job site/truck inventory:

Enter the ID of the new inventory (must be a valid job ID) and press ENTER.NOTE: Before you create a new inventory you must first create a job in 7-1-1: Job cost description maintenance. Then create the new inventory with an inventory ID the same as the job ID.

Press DEL if you want to delete an inventory. This is normally only done when you are completely through using a job/truck inventory and you want to put it out of commission. This will delete any reference to this job/truck inventory out of the inventory system. Prior to running this procedure, you should requisition any remaining inventory back to stock. After this procedure is run, you should also delete the job cost history for the job associated with this inventory.

TopReally delete ALL of this inventory: NO

If you want to exit this area without doing anything, press just ENTER. If you are sure you want to delete this inventory, type YES ENTER and the inventory will be deleted.

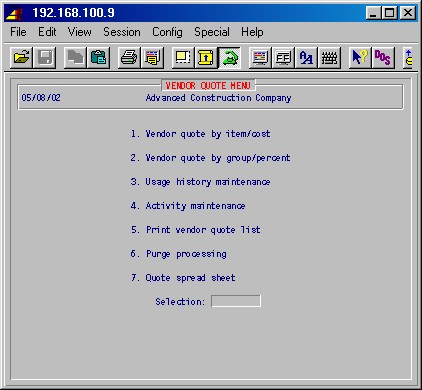

These procedures will allow you record quotes from one or more vendors for each inventory item, print quote lists and spread sheets, and do maintenance on usage history.

This selection will display the following menu screen:

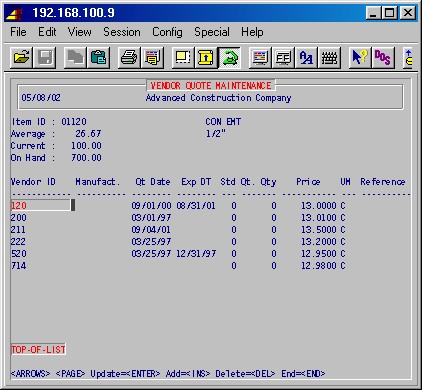

This procedure allows you to record, view, and update quotes from one or more vendors for each inventory item.

This selection will display the following input screen :

Top

Item ID:Type the item ID of the inventory item for which you wish to input a vendor quote and press ENTER. If this is a valid item ID, the system will display the complete description, on hand quantity, current month's and previous three month's usage, and vendor quotes previously entered for this item.Vendor ID

Type the vendor ID [H] for the quote you are entering.Manufact

Optional. Type an abbreviated name for the manufacturer (up to 10 characters).Qt Date

Optional. Type the date of this quote.Exp Date

Optional, but if used, the quote will not be effective after this date. Type the expiration date of this quote.Std

Optional. Type the standard package quantity here (if an item can only be purchased in packages, the system will round the suggested order quantity up or down to the nearest multiple of this quantity.)Qt. Qty

Optional. Type the quantity of this item which the vendor is quoting.Price

Type the actual quote price here in price per unit of measure, or if the reference is a "%" mark, enter the percentage here.UM

The unit of measure, as set up in 8-1 for the item, is automatically displayed.Reference

If the quote price is a percentage (%) of the trade service price, enter a "%" mark here.Use the ARROW, PAGE, ENTER, INS and DEL keys to update, add or delete quotes.

Press END and the screen will be cleared and the system will prompt you for another item ID. You may continue to input vendor quotes or press just ENTER to exit this area and return to the 8-7: Vendor Quote Processing menu.

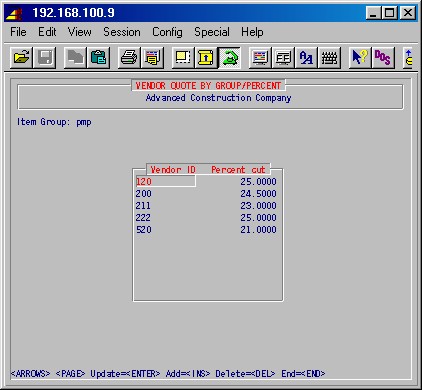

This procedure allows you to record, view, and update quotes from one or more vendors for groups by product code. This selection will first prompt:

Product Code:

Enter the code for the product code group you want. Press ENTER and the system will display the following input screen :

TopVendor ID

Type the vendor ID [H] for the quote you are entering.Percent cut

Enter this vendor's quoted percentage reduction from the trade service end column cost. (The Product Code and Trade Service End Column Cost for an item are shown in 8-1: Non-Abbreviated Entry, as End Clm Cost and Product Code.)Use the ARROW, PAGE, ENTER, INS and DEL keys to update, add or delete quotes.

Press END and the screen will be cleared and the system will prompt you for another product code. You may continue to input vendor quotes or press just ENTER to exit this area and return to the 8-7: Vendor Quote Processing Menu.

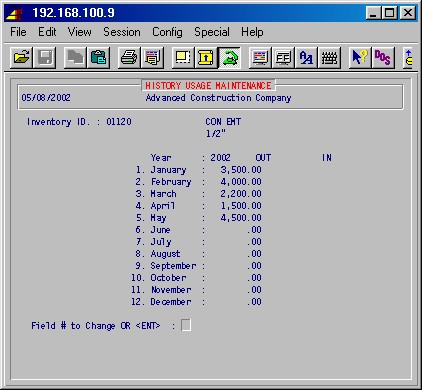

The annual history, by month, for the number of items used of each inventory item is maintained by the system. Normally this history would not be changed manually because the system generates these totals from requisitions, however this procedure will allow you to change the history usage numbers, if required, for any specified item ID.

This selection will display the following input screen :

TopInventory ID:

The inventory ID and name of the currently selected inventory will be displayed.Item ID:

Type the item ID [H] here. If this is a valid item ID, the complete description will be displayed.Year:

Type the year you wish to view and press ENTER.The usage for the year, by month will now be displayed. These fields are in the edit mode, and may be changed, one-at-a-time, pressing ENTER after each. You may press F1 to accept the values in all fields if desired.

When you are finished, you may enter a field number to change or press just ENTER. The system will prompt for another item ID, or press ENTER again to exit this area and return to the 8-7: Vendor Quote Processing Menu.

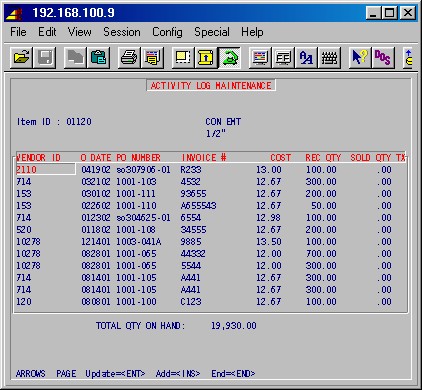

This procedure will allow you to view and edit the item activity log. This

log shows you when and from which vendor a specified item was purchased,

along with the quantity and the cost. Normally this log would not be changed

manually because the system generates

this information from purchases, however items may be edited if required.

You'll first be prompted:

Print or Display?

Type P to print the list, or D to display it on the screen.

If you selected D for display, this selection will display the following screen :

TopItem ID:

Type the item ID for the item you wish to view or edit here. If it is a valid item ID, the system will display the complete description and a list of purchases of this item.You may now use the ARROW, PAGE, ENTER and INS keys to update existing and add new entries. When you are finished press END. The system will prompt for another item ID, or you may press just ENTER to exit this area and return to the 8-7: Vendor Quote Processing Menu.

If you selected P for print, this selection will prompt:

Item ID:

Type the item ID for the item you wish to list. If it is a valid item ID, the system will display the complete description.Beginning job:

Ending job:Enter a job ID range to limit the report to those jobs, or leave blank for all jobs.Beginning date:

Ending date:Enter a date range to limit the report to those dates, or leave blank for all dates.Next the printer selection screen will appear, and when entered the report will print.

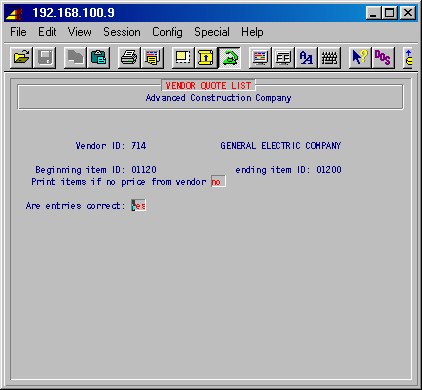

This procedure will print a report by vendor showing any previous quotes for a specified range of item IDs. The report details the item ID, complete description, manufacturer, stock number, date of quote, quantity, and price.

This selection will display the following input screen :

TopVendor ID:

Type the vendor ID [H] for the vendor's quotes you wish to print.Beginning item ID:

Ending item ID:Type the range of item IDs you want to print by specifying the beginning and ending item IDs.Are entries correct:

Check you work. If you need to make changes, type NO ENTER. When you are ready to continue type YES ENTER.The printer selection screen will now be displayed. Type the printer number and the number of copies and press ENTER and your report will be printed.

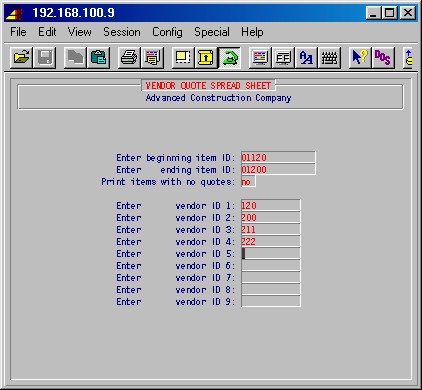

This procedure will print a spread sheet of quotes for a specified range of item IDs for up to nine specified vendors. The vendor quotes must have previously been entered into the system.

This selection will display the following input screen :

TopEnter beginning item ID: Enter ending item ID:

Type the range of item IDs you want to print by specifying the beginning and ending item IDs.Enter vendor ID 1 - 9:

Type the vendor IDs, up to a maximum of nine, for which you want to compare quotes.The printer selection screen will now be displayed. Type the printer number and the number of copies and press ENTER to print your spread sheet.

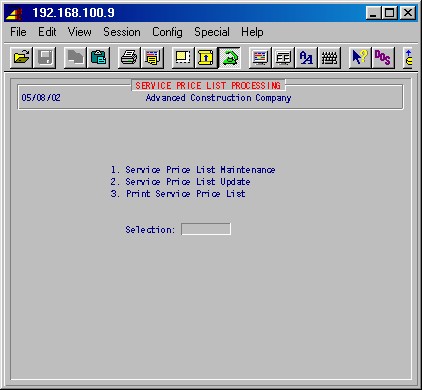

The procedures in this area allow you to identify, price, and produce a list of inventory items that you want the service technicians to carry with them in their service trucks. This list will assist the technicians in pricing the parts used on a service order to enable them to deliver an invoice at the time the service is performed.

The first selection allows you to "tag" those inventory items you want to put on the list. Then, in the second selection, you define the multiplier to be applied to cost for these items to calculate the retail price to be shown on this service order price list. The third selection allows you to print these service price lists.

This selection will display the following menu screen:

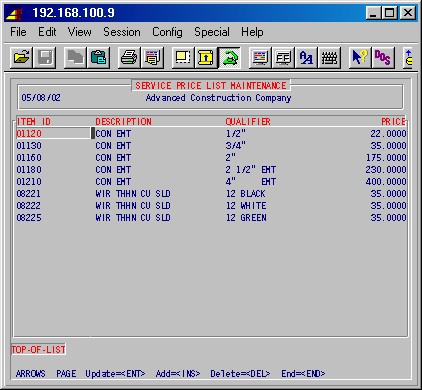

This selection allows you to create and maintain a list of those inventory items you want to put on a printout of inventory items to be carried with your service technicians on service calls. These must be items that are in your other inventories that you simply want to price separately and list on a printout instead of the entire inventory list. These items are entered by item ID and will show the complete description and the selling price.

If there are previous entries in this area, the system will display them as in the example below. If there are no entries, the system will first prompt:

NO ENTRIES ADD: yes

Press just ENTER and the system will display the following input screen :

TopYou may view all of the entries, a screenfull at a time, by using a combination of the ARROW, PAGE and HOME (first/last) keys. If you want to update or delete a line, highlight the item ID, and press DEL or ENTER.

If you want to add an item, press INS and enter the ITEM ID. If this is a valid item ID, the system will display the description, qualifier, and the price (the price is also accessible as "Weight" in the 8-1: Non-Abbreviated Item Maintenance Screen).

To leave this area, press END and the system will return you to the 8-9: Service Price List Processing Menu.

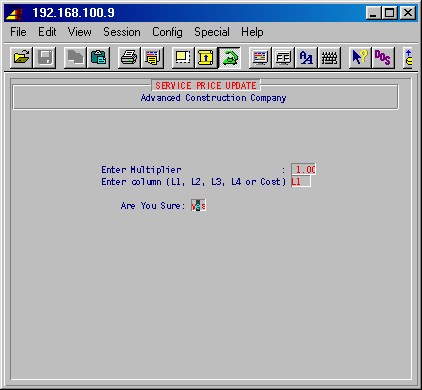

This selection allows you to define the multiplier to be applied to cost or one of the four list prices, for the items listed in step 8-9-1 above, to calculate the retail price to be shown on this service order price list. This selection will display the following input screen :

Enter multiplier:

Type the multiplier (cost x multiplier = selling price) and press ENTER.

Enter column (L1, L2, L3, L4 or Cost)

Select which price or cost is to be used as basis for calculating the service price. Type L1, L2, L3, L4 or Cost and press ENTER.

Are You Sure:

Press just ENTER if you want to exit without making a change. If you want to change the multiplier to the one just entered, press YES ENTER.

The price list will now be updated and the system will return you to the 8-9: Service Price List Processing Menu. If you wish, you may now view the new prices by selecting step 8-9-1.

This procedure will print the service price list you have prepared in the two preceding steps. Selecting this procedure will display the printer selection screen. Type the printer number and the number of copies and press ENTER. Your report will be printed and the system will return you to the 8-9 Service Price List Processing menu.

This selection allows you to specify various units of measure and the count that they represent. The system comes with the most common units of measure as shown in the screen below. This selection will display the following input screen :

You may view all of the entries, a screenfull at a time, by using a combination of the ARROW, PAGE and HOME (first/last) keys. If you want to update line, highlight the line, and press ENTER.

If you want to add an item, press INS and enter the UOM and Count.

If you want to delete a line, highlight it and press DEL.

Be careful not to delete or change any UOM which has already been used somewhere in the system!

When you are finished press END and the system will return you to the #8 Inventory Control Menu.

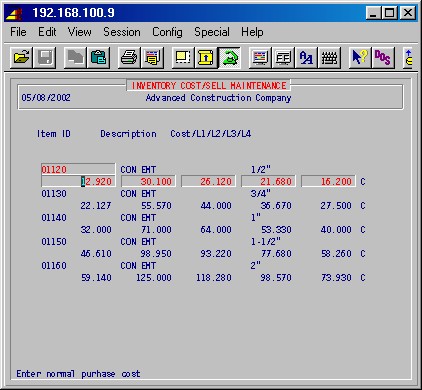

TopItem cost normally is not changed manually because this is updated when you enter the cost in inventory receiving maintenance. However, this procedure will allow you to input new cost and price data for specified item IDs for all inventories. You'll first be prompted:

Update costs (or sell prices)

To update costs type C, to update sell prices type S; press ENTER. If you selected S above, this selection will display the following input screen :

Enter item ID:

Type the item ID for the item you want to enter the new cost. If this is a valid item ID, the system will display the complete description and the unit of measure of this item for verification.

Enter new cost:

Type the new cost figure here and press ENTER. The system will now prompt for a new item ID. When you are finished, press ENTER again and you will return to the Inventory Control Menu.

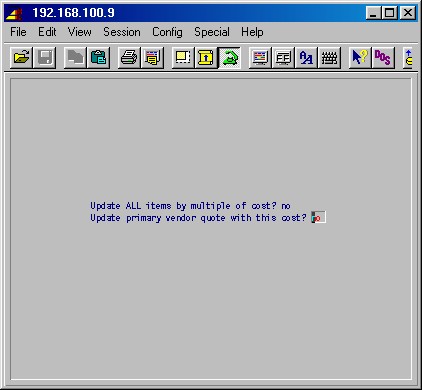

If you answered S above, you'll next be prompted:

Update ALL items by multiple of cost?

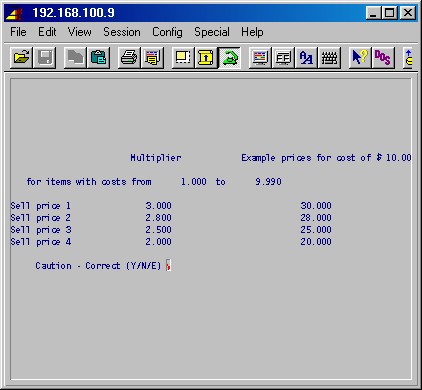

If you answer No to this you will be prompted for item IDs and allowed to enter each of the four sell prices as shown on the above screen, item by item. If you answer Yes here, the system will display the following input screen :

Multiplier

You'll be prompted for a multiplier for each of the four sell prices, and the system will show the resulting price on a $10 cost item.

Caution - Correct (Y/N/E)

If you a really sure that you want to calculate and set the sell prices for all items in all inventories, type Y and press ENTER.TopIf you need to go back and correct one or more of the multipliers, type N and press ENTER.

To abandon this operation without making any changes, type E and press ENTER.

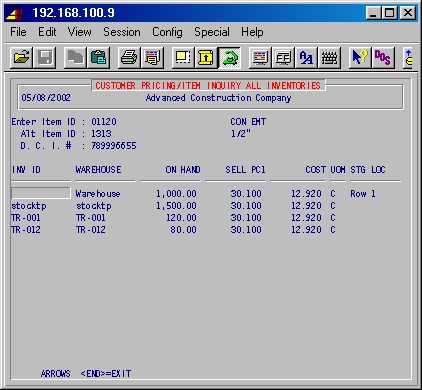

This procedure allows you to display inventory information for a specified item ID. The system will display current inventory locations, quantity on hand, list selling price, and cost price. This selection will display the following data screen :

Enter Item ID:

Type the item ID for the inventory item you wish to view. If this is a valid item ID, the system will display the complete description as well as the location, quantity, list price 1, and cost information as shown above.

Press the space bar or ENTER and the system will prompt you for another item ID. To exit this area, press ENTER again and you will return to the Inventory Control Menu.

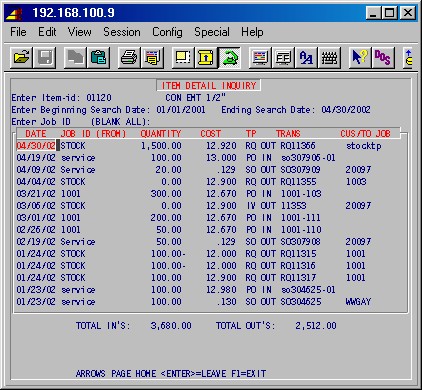

TopThis procedure provides an alternative method of looking at the various transactions for an item.

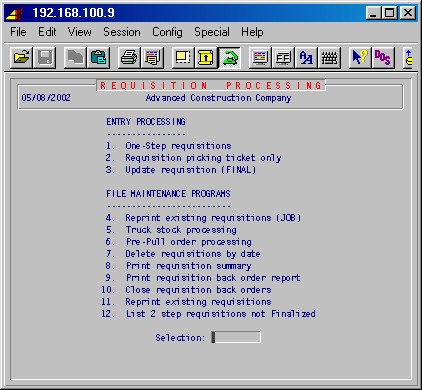

These procedures allow you to create and print requisitions, as well a perform

various requisition maintenance activities. You may requisition material from

the main stock inventory to a job, a job site inventory, a truck inventory or

a service order, or requisition from the job or truck

inventory back to the main stock inventory, or from one truck inventory to another.

You may choose between two basic methods of creating a requisition depending on your operating policies or preferences as follows:

One-step requisitions (step 8-16-1)

This procedure is usually used if you are sure the material is on the shelf

and you want to create and finalize a requisition in one step without creating

a picking ticket before the requisition is finalized.

Two-step requisitions (steps 8-16-2 and 8-16-3)

These procedures are usually used if you are not sure the material is on the

shelf and you wish to issue a picking ticket and physically pull the material

out of the warehouse before you finalize the requisition. You first issue a

picking ticket with step 8-16-2, and then finalize the

requisition with only the material picked off the shelf in step 8-16-3.

This selection will display the following menu:

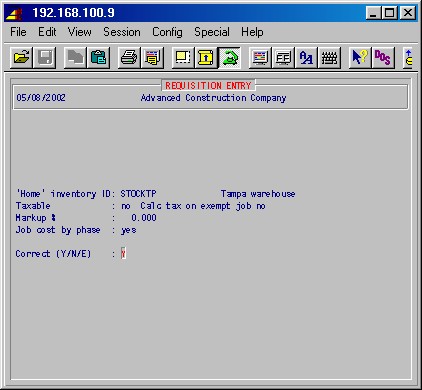

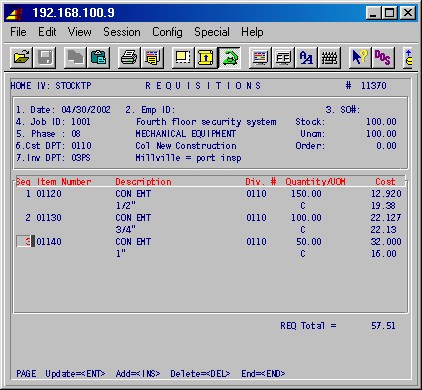

This procedure will create and print a final requisition in one step without first creating a picking ticket. This procedure is usually used if you are sure the material is on the shelf and you do not need to create a picking ticket before the requisition is finalized. This selection will display the following input screen :

'Home' inventory ID

This is the inventory ID of the inventory from which you will be requisitioning this material. The default home inventory is Stock which is the main stock inventory.

This default Stock is used for any requisitions to or from the main stock inventory. Requisitions from jobs or trucks back to the main stock inventory are entered with negative quantities.

On all other requisitions, from truck to truck, truck to job, job to truck, or job to job, type the inventory ID here for the inventory from which you will be requisitioning material.

Taxable

If you will be calculating state sales tax on this requisition, type Yes here.

Markup

Specify a percentage markup to apply to this requisition if required.

Job cost by phase

Answer YES if different phases must be used for different line items.

Correct (Y/N/E)

Type No ENTER to go back and make changes, or End ENTER to end this procedure and return to the 8-16: Requisitions Menu. When you are ready to continue, type Yes ENTER and the following input screen will be displayed :

Top1. Date

The system will suggest today's date for the requisition date. You may specify another date or press just ENTER.2. Emp ID

Optional. Specify the employee ID of the employee requesting this requisition or press just ENTER to leave this field blank.3. SO#

Optional. If a valid SO number is specified, then all items requisitioned will automatically be added to the list of items used on the service order.4. Job ID

Specify the job ID [H] and press ENTER. If this is a valid job ID, the system will display the job name.5. Phase

Specify the phase [H] and press ENTER. If this is a valid phase for this job, the system will display the phase description.6. Cst DPT

Specify the sales department [H] for cost and press ENTER. If this is a valid sales department, the system will display the department name.7. Inv DPT

Specify the sales department [H] for inventory and press ENTER. If this is a valid sales department, the system will display the department name.The system will display the following prompt:

NO ENTRIES ADD: YES

Press just ENTER to continue and enter the material list. The system will display an input area to enter the material with the following fields:

Seq

Each item is numbered by the system as you enter it and displayed with consecutive sequence numbers.Item number

Specify an inventory item ID and press ENTER. If this is a valid item ID, the system will display information about this item in the following fields:Description

This is the description of this item including the qualifier as entered in inventory item maintenance.Cost

This is the cost + markup per unit-of-measure.Stock

This number represents the quantity of this item in this inventory.Uncm

This number represents the uncommitted quantity of this item in this inventory.Order

This number represents the quantity on order with POs.Div. #

Enter the GL division for this requisition, if any.Quantity/UOM

With the description, cost, and unit of measure of this item displayed for your reference, you may now enter the quantity of this item for this requisition. The extended cost of the specified quantity of this item will now be displayed under the cost amount.REQ Total

This field shows you a running total of this requisition as the items and quantities are entered.Continue entering items and quantities until the requisition is completed. You may review the entire list by using the ARROW and PAGE keys. Items may be deleted by pressing DEL and a highlighted line updated by pressing ENTER. Press INS to add more lines.

When you are finished, press END. The system will prompt:

Print Field Copy : NO

If you also want a field copy (picking ticket) printed showing only the item number and description and the amount ordered, with no dollar figures, press YES ENTER. If you want only the complete requisition to print, press just ENTER.

Post to category: (blank for default)

If you want the cost to be posted to some other phase expense category than the default (M), enter it here. Valid choices are L, M, N, C, E, S, O, B and H.

The printer selection screen will now be displayed. Type the printer number and the number of copies and press ENTER. Your requisition will be printed and the system will prompt:

Did requisition print OK YES

Check the printed requisition. If you need to reprint for any reason, type NO ENTER to automatically reprint. Press just to continue. The inventory totals will be updated from this requisition and the system will return you to the bottom of the first input screen in this section.

You may now create another requisition from the same inventory with the same setup information by pressing Yes ENTER and continuing. Press No ENTER to change this screen for another requisition, or press End ENTER to return to the 8-16: Requisitions processing menu.

This is the first step in a two-step requisition procedure. This is generally

used if you wish to create and print a picking ticket first, pull the inventory

out of stock, and then complete the requisition based on what was actually

pulled. This procedure will create the picking

ticket, and step 8-16-3: Update Requisition will complete

the requisition.

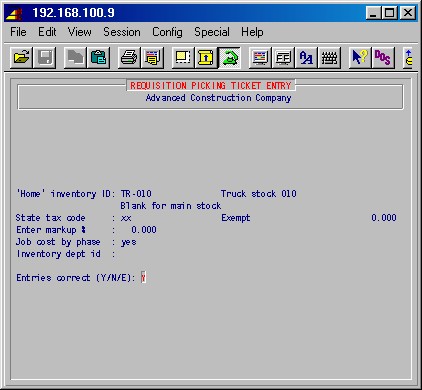

This selection will display the following input screen :

This is the inventory ID of the inventory from which you will be requisitioning this material.

State tax code

If you will be collecting state sales tax on this requisition, type you state tax code here, or type XX if tax is not to be charged.

Other tax code

Not used.

Markup

Specify a percentage markup above cost to apply to this requisition as it is costed to the job, if required.

Job cost by phase

Answer YES if different phases must be used for different line items.

Inventory dept ID

Specify the sales type (department) for inventory cost, if different from cost department.

Entries correct (Y/N/E)

Type No ENTER to go back and make changes, or End ENTER to end this procedure and return to the 8-16 Requisitions menu. When you are ready to continue, type Yes ENTER and the following input screen will be displayed :

1. Date

The system will suggest today's date for the requisition date. You may specify another date or press just ENTER.

2. Emp ID

Optional. Specify the employee ID of the employee requesting this requisition or press just ENTER to leave this field blank.

3. SO#

Optional. If a valid SO number is specified, then all items requisitioned will automatically be added to the list of items used on the service order.

4. Job ID

Specify the job ID [H] and press ENTER. If this is a valid job ID, the system will display the job name.

5. Phase

Specify the phase [H] and press ENTER. If this is a valid phase for this job, the system will display the phase description.

6. Cst DPT

Specify the sales department [H] for cost and press ENTER. If this is a valid sales department, the system will display the department name.

7. Inv DPT

Specify the sales department [H] for inventory and press ENTER. If this is a valid sales department, the system will display the department name.

The system will display the following prompt:

NO ENTRIES ADD: YES

Press just ENTER to continue and enter the material list. The system will display an input area to enter the material with the following fields:

Seq

Each item is numbered by the system as you enter it and displayed with consecutive sequence numbers.

Item number

Specify an inventory item ID and press ENTER. If this is a valid item ID, the system will display information about this item in the following fields:

Description

This is the description of this item including the qualifier as entered in inventory item maintenance.

Cost

This is the cost + markup per unit-of-measure.

Stock

This number represents the quantity of this item in this inventory.

Uncm

This number represents the uncommitted quantity of this item in this inventory.

Order

This number represents the quantity on order with POs.

Div. #

Enter the GL division for this requisition, if any.

Quantity/UOM

With the description, cost, and unit of measure of this item displayed for your reference, you may now enter the quantity of this item for this requisition. The extended cost of the specified quantity of this item will now be displayed under the cost amount.

REQ Total

This field shows you a running total of this requisition as the items and quantities are entered.

Continue entering items and quantities until the requisition is completed. You may review the entire list by using the ARROW and PAGE keys. Items may be deleted by pressing DEL and a highlighted line updated by pressing ENTER.

Press INS to add more lines.

When you are finished, press END.

The printer selection screen will now be displayed. Type the printer number and the number of copies and press ENTER. Your picking ticket will be printed and the system will prompt:

Did picking ticket print OK YES

Check the printed picking ticket. If you need to reprint for any reason, type NO ENTER to automatically reprint. Press just ENTER to continue.

TopThe system will return you to the bottom of the first input screen in this section.

You may now create another picking ticket from the same inventory with the same setup information by pressing Yes ENTER and continuing. Press No ENTER to change this screen for another picking ticket, or press End ENTER to return to the 8-16: Requisitions Processing Menu.

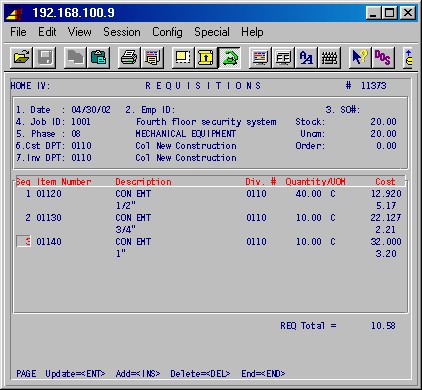

This is the second part of the two-step procedure of creating a requisition.

The picking ticket was created and printed in the first part of this procedure

in 8-16-2: Requisition Picking Tticket Only above.

The picking ticket will have been marked as to what material was

actually shipped.

In this procedure, you will now complete the requisition by marking the quantity of the items shipped. The items and quantities on the original picking ticket which you do not mark shipped in this procedure will be transferred to a new requisition, which will be automatically created. All requisitions with unshipped items will be shown on the back order report, 8-16-9: Print Requisition Back Order Report. This selection will prompt:

Enter requisition # or 99999 for ALL: 00000

Type the job requisition number printed on the top of the picking ticket and press ENTER.

To update all your requisitions, click here.

The system will display an input screen as follows :

This screen looks similar to the original input screen in 8-16-2: Requisition Picking Ticket Only, where this requisition picking ticket was created. This input screen now needs to be updated with the number of each item pulled from inventory and shipped.

To update this list, use the ARROW and PAGE keys to move to the desired item, press ENTER and enter the quantity shipped for the item from the picking ticket.

When you are finished, press END.

Or, if all items have been fully shipped, you may press F1 and the "Shipped" quantities will be set to the "Ordered" quantities for all items and the final posting copy of the requisition will be printed.

The printer selection screen will now be displayed. Type the printer number and the number of copies and press ENTER. The final requisition will be printed and the system will prompt:Did the requisition print OK YES

Check the printed requisition. If you need to reprint for any reason, type NO ENTER to automatically reprint. Press just ENTER to continue. The inventory totals will be updated from this requisition and the system will prompt you for another requisition number.

You may now enter another requisition number from the picking ticket, or press just ENTER to return to the 8-16: Requisitions Processing Menu.

TopIf you want to either mark all items on all your requisitions as shipped, or update them one by one, enter 99999 at this prompt:

Enter requisition # or 99999 for ALL: 00000

The system will prompt:

Really update all your stock requisitions?

Type YES and press ENTER to proceed.All items shipped on all your stock requisitions?

If all items have been fully shipped, type YES and press ENTER and the "Shipped" quantities will be set to the "Ordered" quantities for all items on all your stock requisitions and the final posting copies of the requisitions will be printed.If you want to update each requisition, one by one, without having to enter requisition numbers, type NO and press ENTER. Each requisition will then be presented in turn with an update screen like the one here.

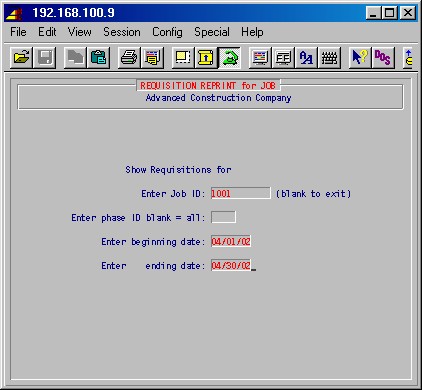

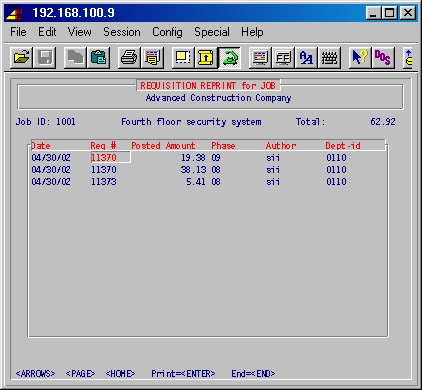

In the steps above, the inventory totals are updated with the printing

of the final requisition. This procedure allows you to view all requisitions

for a specified job and phase for a specified period of time and then reprint

a requisition for any reason without causing the

inventories to be updated again. If you know the requisition number and

do not need to view the outstanding requisitions, step 8-16-11:

Reprint Existing Requisitions allows you to reprint by just entering

the requisition number. This selection will display the following input

screen :

Enter Job ID

Specify the job ID of the job for which you wish to display the outstanding requisitions.

Enter phase ID blank = all

Specify a phase ID or press just ENTER to display the outstanding requisitions for all phases of this job.

Enter beginning date

Enter ending date

Type the range of dates for the requisitions you wish to display and press ENTER. The following screen will be displayed :

TopThe system will display all requisitions for the specified job, phase and date range. Use the PAGE or ARROW keys to scroll up and down through requisition. Press HOME to jump to the first or last requisition.

To print a requisition, use the above keys to highlight the requisition which you wish to print, and press ENTER. The printer selection screen will now be displayed. Type the printer number and the number of copies and press ENTER. Your requisition will be printed and the system will prompt:

Did requisition print OK YES

Type NO ENTER to print again. When the printing is OK, press just ENTER and the system will return to the above screen. Here you may continue to select requisitions to print.

Press END to exit this procedure and return to the 8-16: Requisitions Processing Menu.

These are specialized programs not applicable for most companies.

These are specialized programs not applicable for most companies.

This procedure will allow you to delete requisitions by date. This selection will first prompt:

OK to delete requisitions: ?

Type NO to cancel this procedure and return to the 8-16:

Requisitions Processing Menu.

Type YES to continue. The system will prompt:

Enter cut-off date: / /

Type the date you wish to use as a cut-off date to delete requisitions.

All requisitions dated prior to this date will be deleted. After you have

entered the cut-off date, press ENTER. The system will delete these

requisitions and return you to the 8-16: Requisitions Processing

Menu.

This procedure will print a summary of all requisitions issued through a specified posting date. This report is generally run at the end of each day to have a report which shows what requisitions have been issued. This selection will prompt:

Enter beginning requisition post date: /

/

Enter ending requisition post date: / /

Ok to run report?: yes .

Specify the date and press ENTER. The printer selection screen will now be displayed. Type the printer number and the number of copies and press ENTER.

This procedure will print a report of all requisitions with items and quantities not shipped in the second part of the two-step requisition procedure (step 8-16-3 Update Requisition). This report may be printed grouped by job or by item ID and may be used to prepare a purchase order to re-order these items. This selection will prompt:

Print by job: YES

If you want the list to print by job, press just ENTER. The printer selection screen will now be displayed. Type the printer number and the number of copies and press ENTER. Your report will be printed and the system will return to the 8-16: Requisitions Processing Menu.

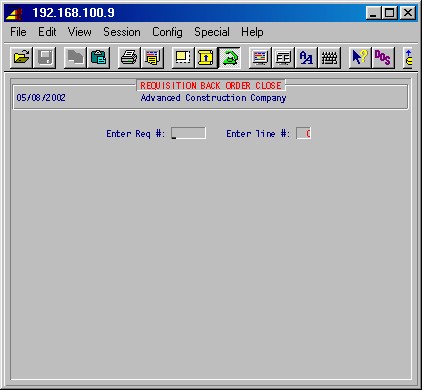

This procedure will close requisition back orders by requisition number and line number of the requisition. This selection will display the following input screen:

TopEnter Req #

Type the requisition number and press ENTER.Enter line #

Type the line number of this requisition which is on back order which you want to close and press ENTER. The system will prompt you for another line number and so on.When you are finished, press ENTER again and the system will prompt you for another requisition number. To exit this procedure, press ENTER again and the system will return to the 8-16: Requisitions Processing Menu.

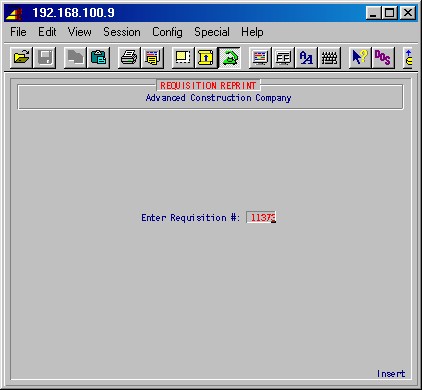

In steps 8-16-1, 8-16-2, and 8-16-3 above, the inventory totals are updated with the printing of the final requisition. This procedure will allow you to reprint requisitions which have not been closed or deleted without updating inventory totals again. This selection will display the following input screen :

TopSpecify the requisition number you wish to reprint and press ENTER. If this is a valid open requisition number, the printer selection screen will be displayed. Type the printer number and the number of copies and press ENTER. Your requisition will be printed and the system will prompt: Did the requisition print ok YES

If the requisition did not print properly, type NO ENTER and you will see the printer selection screen allowing you to select a printer and reprint. If it printed ok, press just ENTER and you will be prompted for another requisition number.

When you are ready to exit this area, press ENTER again and you will return to the 8-16: Requisitions Processing Menu.

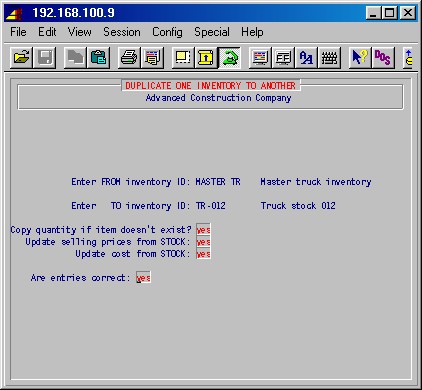

This is a specialized program which will copy an inventory from one inventory ID to another inventory. This is generally used to facilitate copying all of the item ID's in one inventory to a new inventory without affecting requisitions and physical item counts; however, the quantities may be copied if you wish. This program is basically used in the situation where you want to create a new truck inventory and want to make an exact copy of another truck's inventory for the new one.

Typically, a master service truck is set up on the system which contains item

ID's for a standard service truck. Then, when you want to set up a new truck,

this step is performed to copy the master service truck to the new one. The

items are copied to the new truck without taking the

items out of stock or inventory. Requisitions are then make to move quantities

of these items from the source of inventory that is stocking this truck. This

selection will display the following input screen :

Enter FROM inventory ID

Enter TO inventory ID

Specify the "from" inventory ID and the "to" inventory ID.

Copy quantity if item doesn't exist? NO

Press just ENTER if you want to copy over just the item ID's without quantities. If you answer YES, the system will copy all item ID's that are not already present in the copy "to" inventory with the quantity associated with those items in the copy "from" inventory. Any items previously existing in the "to" inventory will be preserved with their current quantities.

Are entries correct: YES

If entries are correct, press just ENTER to perform this procedure.Top

This procedure allows you to set up and maintain product codes. Product codes allow you to identify items in inventory as belonging to groups. At least one product code, na, should be set up.

PC ID

Enter a product code ID of up to 5 characters.

DESCRIPTION

Enter the description of this product code.

COM %

Enter a commission percentage, if applicable.

HS-TP

If you have the Preventive Maintenance Contract module, enter the history type, as set up in 1-4-10: History Type Maintenance, under which you want this product to show.

ZRO-BL

If you enter NO you'll not be allowed to requisition or sell more items than you have; if you enter YES you'll be allowed to go below zero on hand for items with this product code.

SV-TP

You may associate this product code with a service type by entering a service type ID, as set up in 8-19: Service Type Maintenance.

SERVICE TYPE DESCRIPTION

This description will automatically display, once a service type has been entered. When done, press END.Top

This procedure allows you to set up and maintain service types. Service types parallel AR sales types (as set up in 1-4-1: Sales Type Maintenance) and controls your accounting in service, but this feature allows you to have multiple service types without having to set up an AR sales type for each. You need to have one service type for each sales type, but you may have multiple service types pointing toward the same sales type. If desired, you may just set up one service type for each sales type with the service type ID the same as the sales type ID.

ST ID

Enter the ID for this service type, maximum five characters.

DESCRIPTION

Enter the description for this service type.

SLS-TYPE

Enter a valid sales type as set up in 1-4-1: Sales Type Maintenance.

DIV#

Enter the division number, if applicable.

PC-ID

This allows you to associate this service type with a product code, as set up in 8-18: Product Code Maintenance.

DIV #2

Enter a division number for the second division if this service type is to be split between two division.

DV2%

If you entered a division in<blockquote> above, enter the percentage that is to go to this division.

JOB ID

When entering a service order in 2-1, the default job normally comes from the entered dispatch board, as set up in 2-15-3. However, if you enter a job ID here, then that job ID will be used instead when the service type is entered in 2-1.

Use the ARROW, PAGE and ENTER keys to update a line. Press INS to add lines.

Press END when you are done.

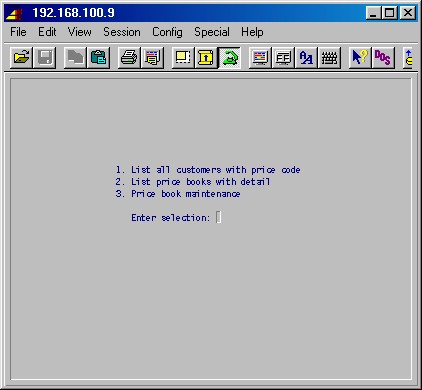

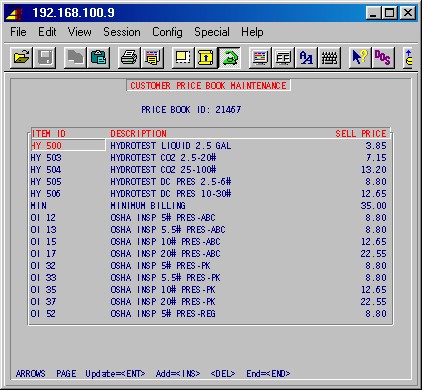

TopThis procedure allows you to set up and maintain alternate prices for items. It will display the following selection menu:

This selection will list all customers which have work addresses with alternate prices with price codes in a selected range, showing price code, customer ID, customer work address number and customer name. You'll first be prompted:

Enter Beginning Price Code:

Enter Ending Price Code: